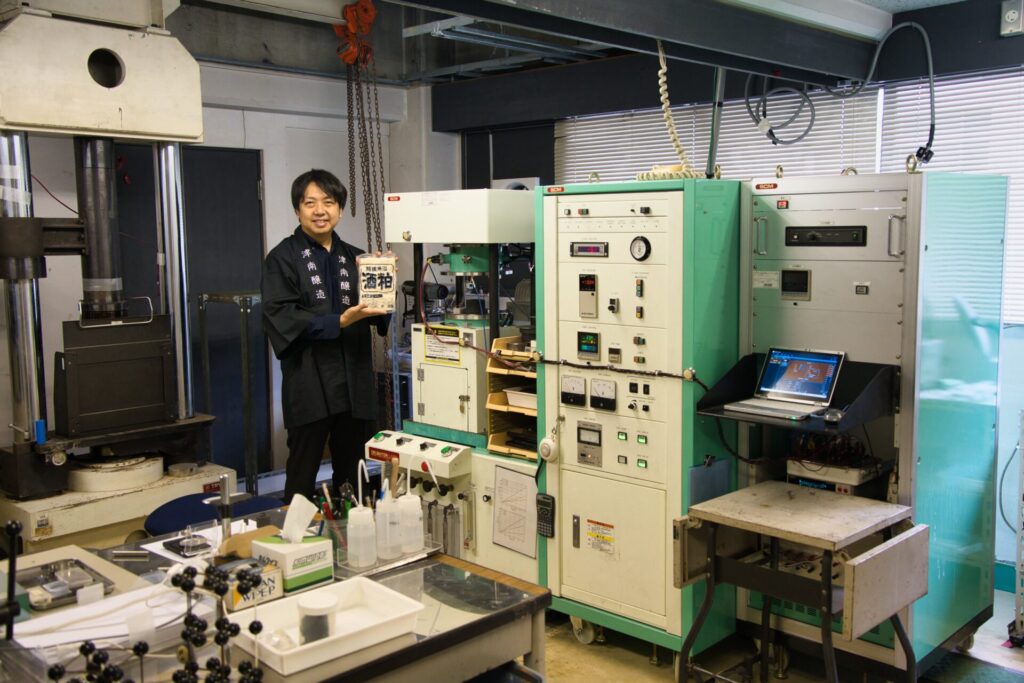

Tsunan Sake Brewery Co., Ltd. (Headquarters: Tsunan Town, Nakauonuma District, Niigata Prefecture; President: Kengo Suzuki; hereinafter “Tsunan Sake Brewery”), is pleased to announce the successful prototyping of graphite derived from sake lees, in collaboration with Professor Yoshihisa Mori of Okayama University of Science and Space Seed Holdings Inc. Tsunan Sake Brewery provided sake lees as the test material for this initiative, which is part of a joint research and development project on next-generation SPS* equipment. The first trial involved sintering sake lees using an SPS device to explore its potential as a carbon-based material.

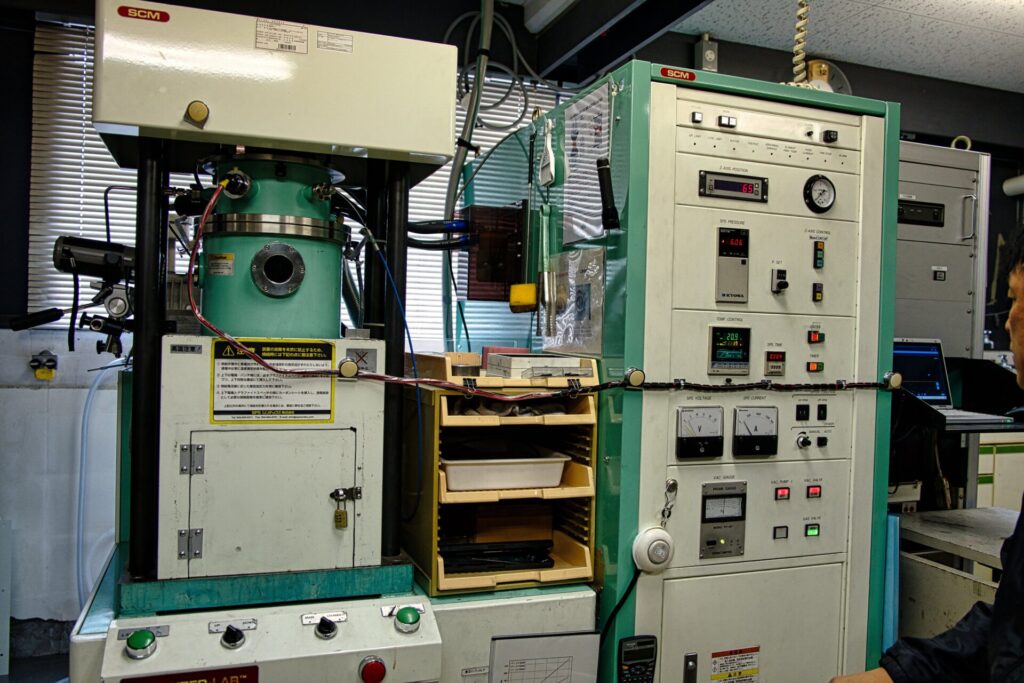

* SPS (Spark Plasma Sintering) is an advanced material synthesis technology that enables rapid, low-temperature sintering by simultaneously applying electric current and pressure to powdered materials. Compared to conventional sintering methods, SPS allows for denser materials with suppressed grain growth. Its applications are expanding in advanced material fields such as nanostructure control and the creation of metastable phases. By optimizing parameters such as pressure, temperature, and current, SPS offers significant potential for sintering challenging materials and developing novel high-performance materials.

Background

As part of its Sake Lees Upcycling Project, Tsunan Sake Brewery is committed to promoting the multi-tier utilization of local resources and advancing circular manufacturing by repurposing byproducts such as sake lees generated from the sake brewing process. This trial was conducted at Okayama University of Science to examine the potential of converting sake lees, a microbe-derived biomass, into high-value-added carbon materials. From an academic perspective, the study aims to clarify how non-carbon components in sake lees affect material properties and conductivity. From an industrial standpoint, the goal is to verify the feasibility of circular manufacturing utilizing microbe-derived raw materials.

Prototype Results

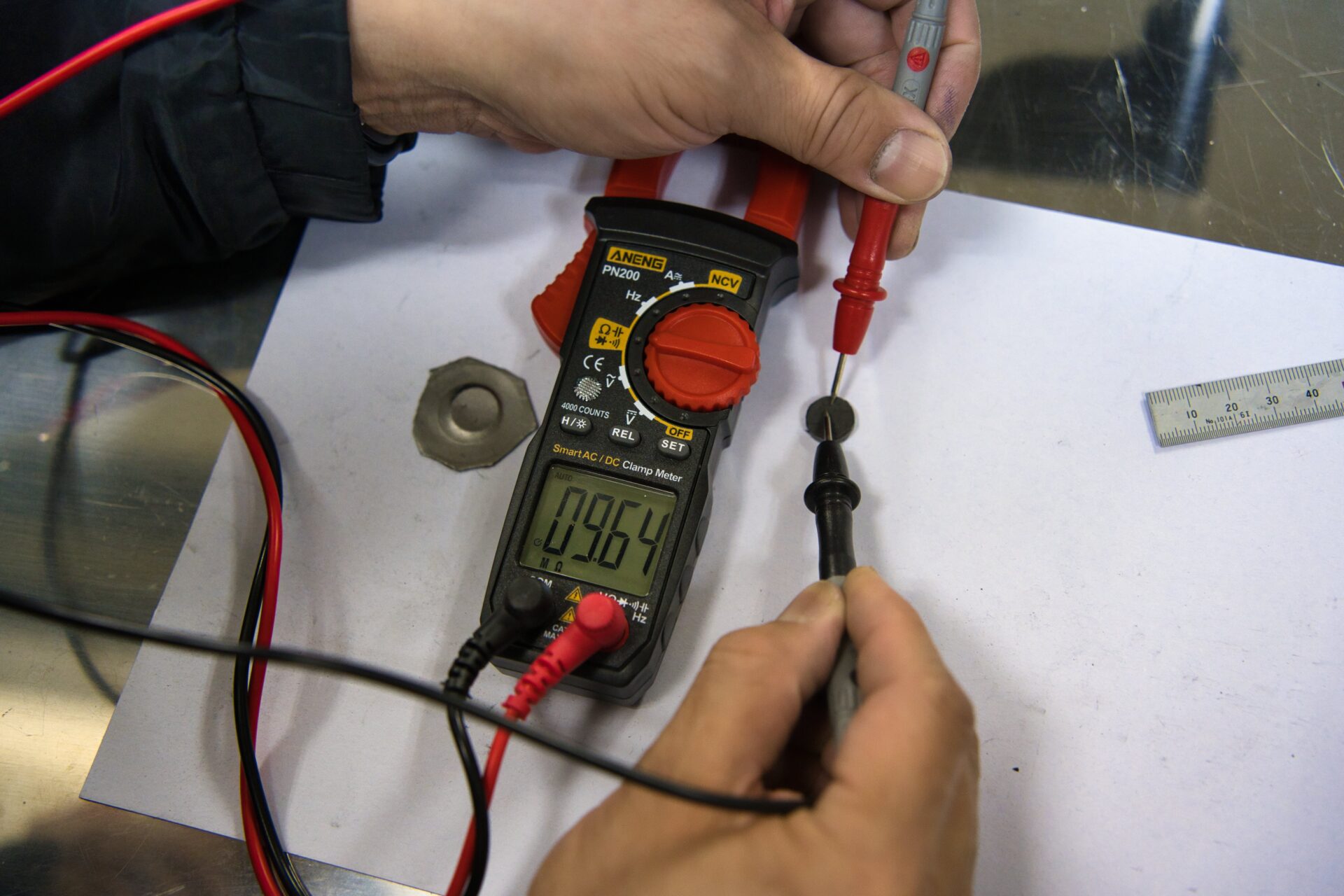

In this initial trial, sake lees were first carbonized in an electric furnace, then pulverized, and subsequently sintered using a conventional SPS device. The process successfully yielded a sintered graphite body with sufficient hardness. Conductivity measurements further confirmed the applicability of sake lees-derived carbon resources, demonstrating the material’s potential for future development.

Future Outlook

Looking ahead, Tsunan Sake Brewery plans to pursue new carbon-framework materials through high-temperature and ultra-high-pressure sintering processes, leveraging the next-generation SPS equipment currently under development by Okayama University of Science and Space Seed Holdings, scheduled for advancement in FY2025. In addition, the company aims to explore the potential for producing advanced materials such as sake lees-derived carbon nanotubes, sake lees-derived graphene, and sake lees-derived diamond semiconductors, by applying insights gained from this research.

Tsunan Sake Brewery will continue to collaborate with public research institutions, private companies, and local governments to pioneer innovative applications of sake brewing byproducts like sake lees. Through these efforts, the company aims to promote circular innovation based on Japan’s primary industries.

About the Sake Lees Upcycling Project

The Sake Lees Upcycling Project by Tsunan Sake Brewery seeks to promote circular manufacturing and multi-tier utilization of regional resources through the innovative use of sake brewing byproducts such as sake lees. The project goes beyond conventional food applications, expanding into areas such as semiconductor materials and conductive materials derived from sake lees, research on sake-derived nanoparticles “SAKESOME,” and even the exploration of using sake brewing byproducts as raw materials for cultured food production. Tsunan Sake Brewery is committed to creating new value across diverse fields, including food, beauty, environment, and biotechnology, from the byproducts of this traditional industry.

About Tsunan Sake Brewery

Tsunan Sake Brewery Co., Ltd. is a sake brewery headquartered in Tsunan Town, Nakauonuma District, Niigata Prefecture, Japan. Located in one of Japan’s heaviest snowfall areas, the brewery utilizes pristine natural spring water sourced from 2,000-meter-class mountains. Tsunan Sake Brewery’s sake brewing incorporates locally grown sake rice varieties such as “Gohyakumangoku” and “Uonuma Koshihikari,” blending tradition and innovation in harmony with nature. Under the brand concept “Brew for Future—Brewing a Sustainable Future,” the brewery strives for excellence, which was recognized in 2025 when it won the Niigata Governor’s Award (1st place) at the Echigo-ryu Sake Brewing Technology Championship.