Niigata, Japan – Tsunan Sake Brewery Co., Ltd. (Headquartered in Tsunan Town, Niigata Prefecture, CEO: Kengo Suzuki, hereafter referred to as Tsunan Sake Brewery) is proud to announce the development of a new kind of sake, utilizing Euglena powder in its production process. This initiative has been accomplished in collaboration with Euglena Co., Ltd. and FERMENT8 Co., Ltd. The newly developed sake, named “Green Sake,” has been introduced at the 100th Anniversary Project “Experiencing Agricultural Chemistry” at the 2024 Annual Meeting of the Japanese Society of Agricultural Chemistry in Tokyo.

Background of Research

Numerous projects by governments and corporations focus on sustainable production systems for energy and food resources through the fixation and resource utilization of carbon dioxide by microalgae. Among these, research on fermentation to explore high-value materials has been significant. Tsunan Sake Brewery, aiming for the fusion of brewing and science, has advanced its research and development in fermentation. The “Green Fermentation” process utilizing algae, specifically by adding Euglena powder, aims to alter the progression pattern of fermentation, thus enhancing the brewing of sake.

Manufacturing Process Utilizing Euglena Powder

As an application of fermentation cases, Euglena powder was used in the yeast activation process of sake brewing. The brewing was conducted in a facility capable of producing over 10 liters, comparing batches made with (Green Sake) and without Euglena powder (Control).

Filtration process of produced sake

Evaluation of “Green Sake”

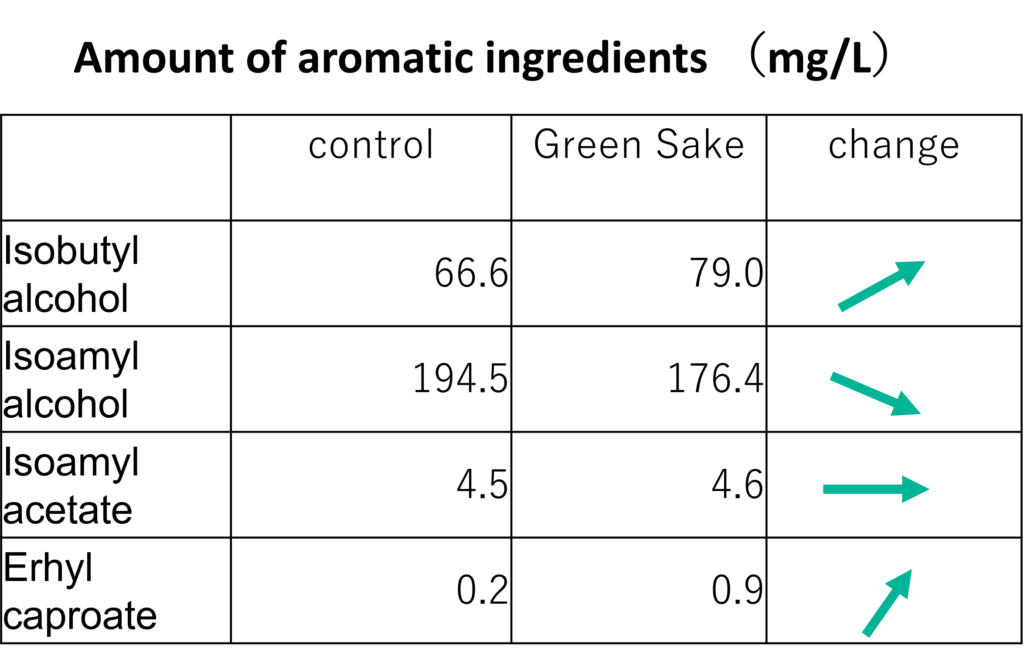

Chemical Analysis Results: The comparative analysis of components between the control and Green Sake, utilizing chemical analysis instruments, suggested that the addition of Euglena powder improved the ratio of isoamyl acetate to isoamyl alcohol, indicating enhanced esterification efficiency. An increase in ethyl caproate content was also observed.

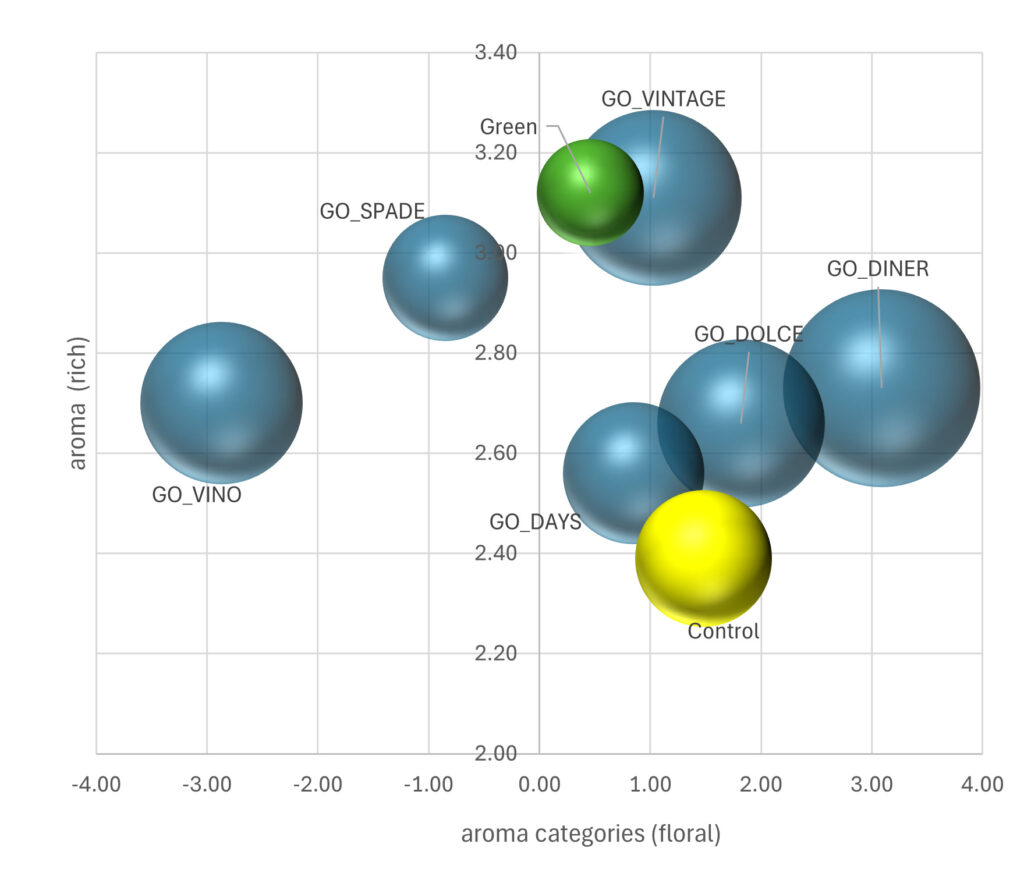

AI Sensory Evaluation Results: An AI-driven sensory evaluation by NOMURA JIMUSHO, INC. using the “ProfilePrint” food analysis device revealed distinct differences between the control and Green Sake.

Results plotted including comparisons with six types of sake conventionally made at Tsunan Sake Brewery. (Yellow is the control and green is “green sake. The size of the circles indicates the numerical size of the sweetness parameter).

The addition of Euglena powder resulted in a sake with subdued “floral” notes, enhancing the “richness” of the rice flavor and aroma, leading to a “cleaner” sake experience.

Reported at the 100th Anniversary Project of the Japanese Society of Agricultural Chemistry

The research findings on Green Sake were presented at the “Experiencing Agricultural Chemistry” event on March 26th, part of the 100th Anniversary Project at the 2024 Annual Meeting of the Japanese Society of Agricultural Chemistry in Tokyo.

Future Developments

The Green Sake will be showcased at the “SHINAGAWA TECH SHOWCASE” from March 27th to March 29th, 2024. Moving forward, Tsunan Sake Brewery aims to implement new brewing techniques that alter yeast fermentation patterns, incorporating AI technology to introduce new forms of fermentation to society.

About Tsunan Sake Brewery Co., Ltd.

Tsunan Sake Brewery is located in Tsunan Town, Nakauonuma District, Niigata Prefecture, a region known for its heavy snowfall and natural spring water from mountains reaching 2,000 meters. Using locally produced sake rice “Gohyakumangoku,” the brewery commits to coexisting with nature, embodying the brand concept “Brew for Future – Brewing a symbiotic future.” With a new direction since 2023, Tsunan Sake Brewery strives for innovative value creation and international expansion, merging the art of sake brewing with science.

https://tsunan-sake.com/.